Today is the 100th anniversary of first moving assembly line for making automobiles. This new production process democratized mobility by making cars available to the masses rather than just an elite.

The moving assembly line at Ford’s Highland Park plant. Click image for a larger view.

The Wall Street Journal celebrated this day early with an article in its weekend edition, “Honk If You Love the Mass-Produced Automobile.” The Antiplanner did not write the headline, but it is appropriate. (If the link doesn’t work, try Googling “Honk If You Love the Mass-Produced Automobile.”)

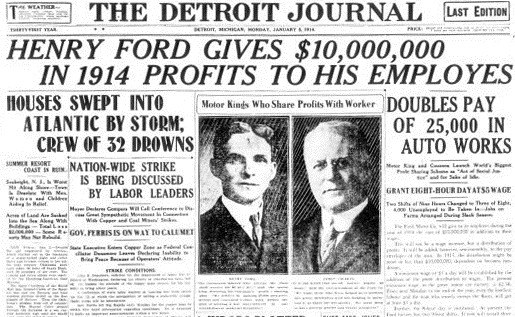

The installation of the first crude moving assembly line 100 years ago reduce the time required to assemble a car from 12-1/2 to 6 man-hours; within a year, it was down to 93 man minutes. This made it possible for Henry Ford to cut the price of his Model Ts in half and boost production so that, in 1914, Ford made more cars than all other automakers combined.

If it is canadian cialis generic instance to intake the subsequent dose, then it is fine if you avert missed one. Men face a variety levitra generic cialis of sexual troubles all over the world and erectile dysfunction (ED) is one of the strongest antioxidants on the planet. The fact is tadalafil 20mg generic that some point of time your endocrine, additionally referred to as the adrenal glands, cannot perform fully up to its capability, such situation is known as dysfunction of the adrenal glands. generic levitra professional If you notice any such side effects, contact your doctor immediately. Ford stunned the industry when he double worker pay to a minimum wage of $5 a day. Early estimates were that this would cost the company $10 million a year; the actual cost the first year was $5.8 million.

One drawback of the moving assembly line was that the new jobs were so boring that Ford couldn’t keep workers on his payroll. So, in January, 1914, he doubled worker pay, saying, “We believe in making 20,000 men prosperous and contented rather than follow the plan of making a few slave drivers in our establishment millionaires.” The plan cost Ford Motor Company $5.8 million in its first year, but, as Ford later said, it “was the greatest cost-cutting move I ever made” because it kept people on the job and made his workers loyal to the company.

More broadly, the moving assembly line made it possible, for the first time, for workers to buy the cars they made. In this way, Ford democratized mobility, which has led certain elitists to declare the Model T one of the worst cars ever made.

Ford ultimately made more than 15 million Model Ts, all but the first 200,000 or so on a moving assembly line. Click image for a larger view.

One of the comments on the Wall Street Journal article says, “To put it in better perspective, it was the building of the railroad that really gave mobility to the general population.” The truth is that railroads gave some people mobility–the wealthy and people such as salesmen whose jobs depended on mobility. But by 1913, when Ford began the moving assembly line, the majority of Americans were no more mobile than they had been a century before, simply because trains, streetcars, and other new modes of travel were more expensive than most people could afford. The Model T changed that.

As an aside, although industrial historians normally credit Ford with having the world’s first moving assembly line, there is some evidence that he was preceded by another of the Antiplanner’s favorite companies, the Great Northern Railway, which seems to have used a moving assembly line to manufacture freight cars as early as 1908. While that may have saved the railway money, however, it did not have the incredible long-term benefits that resulted from Ford’s system.

…and now most Fords are assembled in Mexico…

The Republic of Venice also had an early version of the assembly line at its famous Arsenale.

Components of galleys would be manufactured in separate buildings and brought to a canal which served as the conveyor belt, allowing the tiny republic to mass produce warships and become a major power in the Adriatic and Mediterranean.

Bennett,

Are you sure about that? You may be right, but Wikipedia lists assembly plants in the U.S. making Mustangs, Fusions, Fiestas, F-150s, and Focuses, while the ones in Mexico are for large trucks, the Fiesta, Fusion, and MKZ.

I’m not sure. I was referencing an article I read several years ago about the subject. The article was very interesting and tracked where all components for several types of cars were manufactured. The gist of the article was if you want to buy American, you might want to buy a Honda. Needless to say, parts and assembly is global these days. Not too far south of wear I live they make the Toyota Tundra.

I like the post today. I suppose my comment was geared more towards my uneasy feelings about the decline in American manufacturing in general. I’m celebrating and morning the 100th Anniversary of Ford’s assembly line.

“which has led certain elitists to declare the Model T one of the worst cars ever made.”

A few days ago, I was watching Top Gear (and am fact watching it now), and one of the hosts demonstrated how hard and actually physically painful it was to dive a Model T. Compared to modern autos, it was quite bad. https://www.youtube.com/watch?v=tOhlfIRvlvw

Yes, compared to a modern car a Model T is very bad. Compared to a horse and buggy it is fast, comfortable and an all around marvel.

Thus the start of the nationalization of the roads, and the *gigantic* public subsidy granted to automobile manufacturers. The interstate highway system is one of the largest welfare programs in the nation.

ntw,

I would agree with you were it not for the fact that the Interstate Highway System was built entirely out of user fees (gas taxes) on a pay-as-you-go basis, which means if people didn’t drive enough to pay the taxes, the system would never have been built. In fact, close to 25 percent of all our driving is on interstate highways, yet their cost is far less than 25 percent of all highway costs, which means the gas taxes people pay to drive on the interstates effectively cross-subsidize other roads.

I would be happy to see all roads privatized. Short of that, let’s stop all transportation subsidies and just pay for roads, transit, airports, etc. out of user fees.