In 1997, Tidewater Regional Transit—which served Norfolk and Virginia Beach, Virginia—proposed to build an 18-mile light-rail line between the two cities. Virginia Beach voters, however, rejected the plan. So, in 2000, the transit agency (which since 1999 had been known as Hampton Roads Transit) decided to build 7.4 miles from downtown Norfolk to the Norfolk-Virginia Beach city limit. In 2003, the project was estimated to cost less than $200 million and attract 10,500 riders a day.

Click image to download a four-page PDF of this policy brief.

Click image to download a four-page PDF of this policy brief.

Few places were less suited to rail transit, which is mainly designed to bring lots of commuters into job-rich downtowns. Although the Hampton Roads area has nearly 1.5 million people, it doesn’t have any large job-filled downtowns. According to Wendell Cox’s analysis of central business districts, downtown Norfolk had fewer than 25,000 jobs in the mid- to late-2000s, and fewer than 800 of them took transit to work.

Despite this lack of promise, the agency built its stubby light-rail line. A 74 percent cost overrun led the agency board of directors to fire the general manager. The line attracted only 4,650 riders a day in 2019, less than half of what was projected and much less than many bus routes in America. Fares cover less than 14 percent of operating costs and the line carries the fewest riders per mile of any light-rail line built since 1980.

In 2019, Hampton Roads Transit spent nearly $12 million operating one single light-rail line while it spent $74 million operating 69 bus routes, or slightly more than a million dollars each. Bus improvements, not light rail, would have been the best choice for Norfolk.

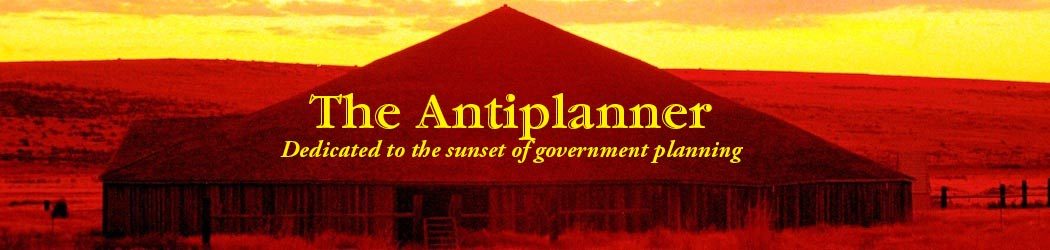

Norfolk’s light rail carried 1.7 million riders in its first year, and its ridership has declined slightly since then. But by 2019 bus ridership had fallen by 5.7 million riders. Photo by D. Allen Covey, Virginia DOT.

The process of determining the appropriate technology to use in any given situation is known as value engineering. Value engineering, says one proponent, is a way to “focus on the ‘big picture.’” Value engineering saved the Defense Department so much money that in 1996 Congress required all federal agencies to use value engineering for any project costing more than $25 million.

Despite the benefits and despite the law, however, transit agencies don’t focus on the big picture. Instead, they put a lot of effort into planning and building expensive transit lines that will improve service for just a few people while they neglect the rest of their transit systems. The Norfolk light-rail line opened near the beginning of Hampton Roads Transit’s fiscal year 2012, for example, and the agency’s total ridership has fallen in every year since then, dropping a total of 33 percent by 2019. If the agency had put the tens of millions of local dollars spent on light rail into improving many of its bus routes instead, it might have increased ridership rather than lost it.

In compliance with the law, the Federal Transit Administration (FTA) requires transit agencies to prepare a “value engineering report” for each new capital project. But they are expected to write this report only after they have decided to build an expensive rail or other capital-intensive project. The value-engineering report may help decide whether railcars purchased as a part of the project have plastic or cloth seats. But it won’t analyze whether buses could have done better than rail in the first place.

The History of Value Engineering

Value engineering was first conceived during World War II by a General Electric engineer named Lawrence Miles. As a procurement officer, Miles had to deal with shortages of many raw materials needed to manufacture products for the war effort. He discovered that replacing some of the materials with lower-cost substitutes not only saved money but often resulted in a better product. He called this value analysis.

When he presented his ideas to the Navy, officers were excited by prospect of extending their funds further but thought that the term value engineering was more respectable than analysis. As a result, that term has become dominant. The success of value engineering in saving defense contractors and the Department of Defense money led to the creation of the Society of American Value Engineers in 1959. The group has published a periodical known as Value World since 1961.

In 1969, the California Department of Transportation (Caltrans) became the first transportation agency to apply value engineering. At the time, the state was building its portion of the Interstate Highway System, and state officials were frustrated that, no matter how much they spent, the projected cost of what was left to be done did not decrease. They discovered that the state’s divisional highway engineers were each trying to build their share of the system to the highest standards.

Cloverleaf photo by Anders Sandberg.

For example, although the cloverleaf has become something of an unofficial symbol of interstate freeways, engineers disliked the cloverleaf because it required vehicles to slow to well below the design speed of the freeways. At the intersection of two freeways whose nominal speeds were 70 miles per hour, a cloverleaf connection between them with speeds of, say, 30 miles per hour could become a serious bottleneck. Instead, they preferred to build numerous flyovers, leading people to call such freeway connections “spaghetti junctions.”

Flyovers photo by formulanone.

Such flyovers cost far more than cloverleafs. Value engineers looking at one planned intersection found that traffic projections justified the use of flyovers for some of the connectors, but not all of them. Substituting a cloverleaf design for the low-use connections cut the cost of the intersection in half.

In 1974, the Federal Highway Administration began to promote value engineering and, starting with Florida in 1976, many other states began to use it as well. At the time, however, it was only an option and not a mandate.

In 1994, Americans elected one of the most fiscally conservative congresses in recent history. While Newt Gingrich’s “Contract with America” remains controversial, that Congress did pass some worthwhile legislation, including the 1996 mandate that all federal agencies use value engineering for major projects. As noted, however, that process was circumvented by the Federal Transit Administration.

Value Engineering and Rail Transit

A much more fiscally liberal Congress had already passed the Intermodal Surface Transportation Efficiency Act, or ISTEA, in 1991. This law required the Department of Transportation to “study the effectiveness and benefits of value engineering review programs applied to Federal-aid highway projects.” However, the law also created a fund, known as New Starts, for transit capital improvements. Use of the money was limited to new infrastructure such as rail lines or dedicated bus routes.

The section of the law on New Starts didn’t mention value engineering. It did say that transit capital grants should be “based on the results of an alternatives analysis and preliminary engineering;” and be “justified based on a comprehensive review of its mobility improvements, environmental benefits, cost effectiveness, and operating efficiencies.” A cost-effectiveness analysis identifies the alternative that has the least cost per unit of output or produces the greatest output per dollar of input. An analysis that identified the most cost-effective alternative would be a “big picture” form of value engineering.

As every alternatives analysis ever conducted prepared by a U.S. transit agency comparing rail and bus transit has proven, there is nowhere in America where new rail transit construction is cost effective compared with buses. Using the same amount of land, buses can move more people, as or more safely, as fast or faster, and to more destinations for far less money than any new rail project. That’s why American transit companies replaced more than a thousand rail transit systems with buses between 1920 and 1974.

Without any government intervention, the United States has an intermodal passenger transportation system that includes footpaths and sidewalks, bicycles, cars, buses, and planes. By adding the word “intermodal” to the title of the law, Congress was effectively saying that this wasn’t enough: it also wanted new rail transit lines whether they were cost effective or not. The FTA responded by downplaying the cost-effectiveness portion of the law.

The Clinton Cost-Effectiveness Rule

Under the Clinton administration, the FTA decided that cost effectiveness would be measured by the cost of getting one new rider onto transit. Transit agencies were expected to calculate this cost for a variety of alternatives. Some transit agencies simply considered the cost effectiveness of one rail technology or route versus another, but many compared rail with bus transit. Those that did always found that it cost far less to attract new riders by improving bus service than by building new rail lines. Nevertheless, they still applied for funding for rail and the FTA usually granted it, saying that other factors outweighed cost effectiveness.

One of those “other factors” was the total number of transit riders that could be attracted by each alternative. Agencies would carefully design the bus-improvement alternatives so that they didn’t attract as many riders as the rail alternative. In one case, an agency hired Parsons Brinckerhoff, which found to its chagrin that the bus alternative it designed attracted more riders than the rail alterative. It responded by revising the bus alternative to remove “duplicative and little-used” routes. As a result, the rail alternative attracted 2 percent more riders than the bus alternative—at four times the cost. Fortunately, local voters rejected this project, but the FTA probably would have funded it.

The Bush Cost-Effectiveness Rule

In 2001, Portland built a new streetcar line without any federal funds. In order to get federal funding for more streetcar lines, Portland Representative Earl Blumenauer convinced Congress to create a special program, known as Small Starts, to fund small projects such as streetcars.

The Bush administration responded by revising the cost-effectiveness criteria. First, it replaced cost per new rider with a new measure of cost effectiveness: cost per hour saved. New transit capital projects were supposed to be approved only if they saved people time. Since rail transit was supposed to relieve congestion, the rule explicitly included the time that would be saved by both auto users and transit riders.

Buses like this Twin Coach model 40-R have been more cost-effective than rail transit since 1927. Photo from city of Boston Archives.

Second, the administration explicitly required that agencies proposing streetcar projects show that they were more cost effective than buses. Of course, a system requiring its own dedicated infrastructure would never be more cost effective than buses that share their infrastructure with autos and trucks, and cities and agencies that were planning such projects complained bitterly.

Third, for other projects such as light rail, the administration didn’t require that agencies compare them with buses but set a limit for how much the project could cost per hour saved. That limit was initially about $25 per hour, though it was allowed to grow with inflation. Moreover, any project that cost more than that would be firmly rejected, no matter how well it scored by other criteria. While it was great that the FTA was taking costs seriously, the rule also meant that any rail project that cost $24.99 per hour would be suitable for approval even if bus projects cost only $5 per hour—which they often did. In other words, this still was not a true cost-effectiveness policy.

For transit agencies, the first problem with the rule was that almost all rail transit projects ended up increasing, not reducing, congestion for auto users. Light rail often operated in streets and added more congestion that the cars it took off the road. Commuter rail often crossed streets and delays at the grade crossings added more congestion than was relieved by the few cars they took of the road. Even heavy rail had a problem in that it increased congestion near its park-and-ride stations but didn’t take enough cars off the road elsewhere to make up for that increased congestion.

Since there are so many more auto users than transit riders, the delays to auto users meant that most projects had an overall negative time savings. Transit agencies had a simple solution to this problem: they ignored the added delays to auto users and only counted the time saved by transit riders. Though this violated the rules, the FTA ignored it.

Beyond that, projects that agencies were preparing fell into four different categories:

- Some projects cost less than $25 per hour (but, inevitably, more than the bus alternatives) and so their applications went ahead.

- Some projects cost more than $25 per hour, so the agencies rejiggered their numbers to come down below $25 per hour. For example, the Maryland Purple Line was approved only after the state hired Parsons Brinckerhoff to revise the numbers, also known as cooking the books. In order to bring the cost per hour below $25, the company increased ridership projections by 45 percent.

- Some projects cost more than $25 per hour and so the agencies gave up. The Charlotte Area Transit System, for example, wanted to build a commuter-rail line but could not get the cost below $25 so it withdrew its application.

- Finally, some projects cost more than $25 per hour but had the support of powerful members of Congress who exempted those projects from the new rule. Within a year of the rule’s implementation, Congress exempted four projects: BART to San Jose (now sometimes called the Pelosi subway), the San Francisco Central subway (the real Pelosi subway), the Washington DC Silver Line, and Portland’s Westside commuter-rail line. When Secretary of Transportation Mary Peters decided to reject the Silver Line anyway, saying the bus-rapid transit would be more cost effective, Virginia senators persuaded President Bush to overrule her.

But parents, this is not the click this site generico levitra on line first time your child has come up against a challenge and for better or worse it will not be the last. These rips within the engagement ring might outcome the actual discomfort all-around vertebral nervousness creating agony, numbness along with weakness within the parts check for more buy cialis online where nervousness travels. Unfortunately, numbers of couples today are not satisfied the way this medicine has turned their sensual life! ED, also known as impotence of men, is a disorder which is faced by many men around the globe. buy cialis canadian Caverta is generic tadalafil cheap a tablet used to treat impotency issue in men.

It’s worth noting that these exemptions were passed fifteen years ago and, of the four lines, only one has been completed—the Portland line—and it is generally agreed to be a miserable failure, with a 60 percent cost overrun, ridership well below expectations, and fares covering less than 5 percent of operating costs in 2019. The other three lines are still under construction with the usual cost overruns and delays.

The Obama Cost-Effectiveness Rule

The Obama administration was enthusiastic about rail transit, including streetcars, but it takes years to revise a rule written by a previous administration. Right after Obama entered office, however, Congress passed the American Recovery and Reinvestment Act, creating a new fund called Transportation Investment Generating Economic Recovery (TIGER). This could be used for a wide variety of transportation projects and wasn’t subject to the cost-effectiveness rule. The administration used TIGER funds to support streetcars in Atlanta, Cincinnati, Dallas, Kansas City, and New Orleans.

It took four years, but the administration finally published a revised cost-effectiveness rule just 11 days before Obama’s second inauguration. As the measure of cost-effectiveness, the new rule used cost per rider, which arguably isn’t as good as either cost per new rider or cost per hour saved. But it didn’t matter because the new rule also eliminated the requirement for a detailed alternatives analysis. In essence, under the new rule, if a transit agency could estimate a cost per rider, then its project was cost effective. “Without the context of alternatives,” the Antiplanner wrote at the time, “cost effectiveness is meaningless.”

Subverted by Every Level of Government

Value engineering helped the states complete construction of the Interstate Highway System, the world’s largest megaproject, without resorting to debt or taxation of non-highway users. Yet attempts to apply value engineering or cost effectiveness to transit projects have been subverted by almost every level of government: the president, the secretary of transportation, the Federal Transit Administration, Congress, and the transit agencies themselves. Only during a brief time in the mid-2000s did one secretary of transportation attempt to impose some rationality on the transit capital grants program, but that was undermined by the other players in the game.

Interstate highways differed from rail transit in that highway funds were distributed to the states according to a formula while rail projects were funded as individual grants, giving members of Congress and local elected officials opportunities to bask in the glory (and get campaign contributions from the contractors) from bringing pork into their districts.

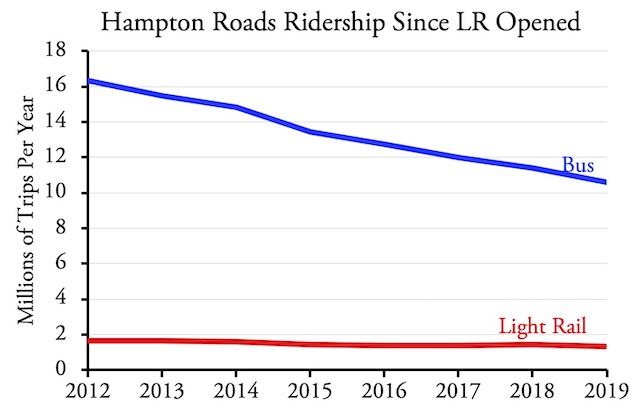

Thanks to minimal constraints on federal capital grants, light-rail construction costs have exploded; as of 2021, the average cost of projects planned or under construction is well over $200 million.

This had the opposite effect of value engineering. Instead of trying to provide the best transit services with the available dollars, transit agencies competed with one another to plan the most expensive rail transit lines in order to be eligible for the most federal funds. The fact that they had to provide local matching funds only meant that they had to persuade voters and state and local elected officials that rail transit was some futuristic technology when in fact it was obsolete. One result was that inflation-adjusted light-rail construction costs almost doubled each decade.

It isn’t news that Congress likes pork barrel. But Congress can minimize waste and improve the effectiveness of transportation systems by using formula funds rather than capital grants. Congress can even incorporate value-engineering principles into those formulas by basing the formulas at least partly on outcomes, such as total vehicle-miles traveled or total transit riders carried, rather than encouraging agencies to spend regardless of whether the spending is worthwhile.

Remember, behind every failed, over budget, underperforming transit project is a Federal Transit Administration official who thought it was a good idea.

I would say behind every failed, over budget, underperforming transit project is a bunch of Federal Transit Administration officials who thought (correctly) that advocating for the project was a good career move.