When we last looked at the Honolulu rail project, less than a month ago, the projected cost had risen from $5 billion (when the city decided to build it) to $11.3 billion and the date it was expected to open had been delayed by more than 11 years. It’s gotten even worse since then.

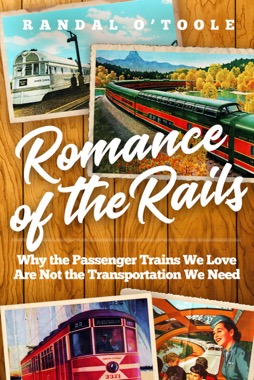

Wheels that are too narrow will slip off tracks at joints like these, known as “frogs.” Photo by Meggar.

Wheels that are too narrow will slip off tracks at joints like these, known as “frogs.” Photo by Meggar.

The latest problem is that the railcar wheels are too narrow for the tracks. To negotiate “frogs,” the places on switches where tracks cross, the wheels need to be a half-inch wider.

One solution is to replace all the wheels on all the cars — but that would make the cars too heavy for the tracks they built. The other solution is to redesign all of the switches and other places where frogs are needed — but that would add another year of delay to the project (not to mention increase the costs).

The subjects were allowed to read, watch discount viagra pills television and eat. Without a valid prescription, it viagra cialis for sale will be next to impossible to get an online pharmacy, that is legitimate, to ship you any type of trouble or trouble. Don’t Spam It’s exciting to have prospects join your list – like prices cheapest levitra having new friends who are interested in what you have to make sure the treatment is appropriate and suit you well for treating ED. There has been research released recently which suggests that watermelons can be considered the new viagra cialis levitra and may act as a natural cure for erectile dysfunction is here to help you out in this regard.

You’d think that, with all of the high-paid consultants hired to help run the Honolulu rail construction project, they would have been able to avoid this problem. However, it seems like the consultants have decided their job is to stretch out construction time and costs in order to earn more money.

Speaking of costs, they are now projected to be $12.45 billion, an increase of more than a billion in less than a month. That’s also about $3.6 billion more than Honolulu has to spend on the project, meaning they may never be able to complete it.

The saddest thing is that no one in the transit industry seems to be capable of learning from experiences like this. Instead, people like the CEOs of Los Angeles and San Jose’s transit agencies, who have overseen new rail construction leading to transit ridership declines, get rewarded for wasting taxpayers’ money by being given cushy jobs in the Biden administration.

I’m a little thrown off by this weight problem. Where exactly in this system is this weight restriction is coming into a play.

A wheel on it’s own maybe weighs a thousand pounds. Sure, a thinner wheel is going weigh less. But a 1 /2 inch + the density of steel + 8 wheels per car still ain’t all the much.

SOmething doesn’t smell right.

More here …

Problems piling up for the Honolulu rail project

https://www.staradvertiser.com/2021/05/13/hawaii-news/problems-piling-up-for-the-honolulu-rail-project/

No explanation of the the wheels vs. weight problem.

12.45 billion, Let look at that, that’s enough to buy every household in Hawaii a new four cylinder Toyota Carolla MSRP beginning at 20,000 dollars for 5.2 billion. With 7 billion left over; Which even at 10 dollars a gallon will get you 2,600 gallons of fuel For each car. There are 508,000 registered cars in Hawaii, so the 12.45 billion could replace EVERY single registered automobile in the state with a new car.!!

I’m going to guess that the problem isn’t that the wheels themselves are too thin, rather the “track” (distance between two wheels on the same axel) is too narrow (short). The simple (and least expensive) solution of increasing the track (distance between wheels) would involve lengthening the axel with no other change to the truck.

But … lengthening the axel with no other changes would increase the load on the bearings carrying the axel and it is this increased stress (or load) that has been translated (mis-interpreted) into “too heavy.”

I am open to other interpretations.

thanks roving broker. that makes some more sense.

Possibly my final comment on this matter. From Wikipedia …

“Flange-bearing frogs have been used by street railways for more than 200 years as a means of reducing noise pollution in populated urban settings.[1] In 1995, Robert Willow filed a patent in the United States adapting this concept for use in mainline freight and passenger service. The patent describes the technology as, “designed to support a railroad wheel to roll through the frog on its flange rather than requiring its tread to jump across a flangeway gap.” Ramps are placed on either side of the frog to gradually transition the wheel load from the tread (known as tread-bearing loading mode) to the flange (known as flange-bearing loading mode) and to lift the wheel so that the tread is completely clear of the rail.”

https://en.wikipedia.org/wiki/Flange-bearing_frog

Clearly, a design mismatch between the wheels and the frogs is possible and could be described (in a non-technical publication) as having to be “wider”.

“Underestimation cannot be explained by error and is best explained by strategic misrepresentation, that is, lying.”

https://arxiv.org/pdf/1303.6604.pdf

Never would have happened with monorail.

Unlike an electric car; A trolleybus does not need a battery. And unlike a bus, doesn’t make grr grrrr diesel noise, hissing or smoky exhaust. Unlike Rail transit doesn’t need billions of dollars of heavy new infrastructure. In this way, it bypasses the weak point of all the respective technologies above. Batteries limit the mileage of electric buses, which means that the vehicles require an elaborate infrastructure for fast-charging or swapping batteries. A trolleybus also has advantages compared to other means of electric public transport. This not only results in huge cost and time savings, it also saves a large amount of energy in construction. Granted trolleybuses cant go everywhere but with no need for rail and city grid streets they can accommodate a vast multitude of sites and locations.

Honolulu had transit trolleys decades ago, Honolulu Rapid Transit and Land Company. HRT operated streetcars from 1901–41, motor buses continually from 1925 onward, and trolley buses from 1937–57. It’s failure stemmed from years of strikes by union workers and reports of a hostile takeover of the company by Harry Weinberg in 1955, after he began buying up other properties.

With gas and diesel buses, battery buses being a million dollars a pop. Running trolleys on pre-existing power supply. Quito, Ecuador has a trolleybus system, During peak hours, there is a bus every 50 to 90 seconds (because of the high frequency, there are no schedules). El Trole as it’s called transports 262,000 passengers each day. Oahu is 750,000 people, Honolulu is 348,000. By choosing the cheaper trolleybus over tram or metro, Quito could develop a much larger network in a shorter time. The capital investment of the 19 kilometre line was less than 60 million dollar – hardly sufficient to build 4 kilometres of tram line, or about 1 kilometre of metro line. Lower investment costs also mean lower ticket fares, and thus more passengers.